Are you sure you want to perform this action?

Opening hours

-

PLEWISKA

- Monday - Friday

- 7:30 - 16:30

- +48 61 60 00 100

- [email protected]

-

CONTACT 24/7

- Contact after office hours

- +48 61 60 00 102

-

KATOWICE

- Monday - Friday

- 7:00 a.m. - 4:00 p.m.

- +48 48 32 88 00 300

- [email protected]

-

OLSZTYN

- Monday - Friday

- 7:00 a.m. - 4:00 p.m.

- +48 89 89 89 350

- [email protected]

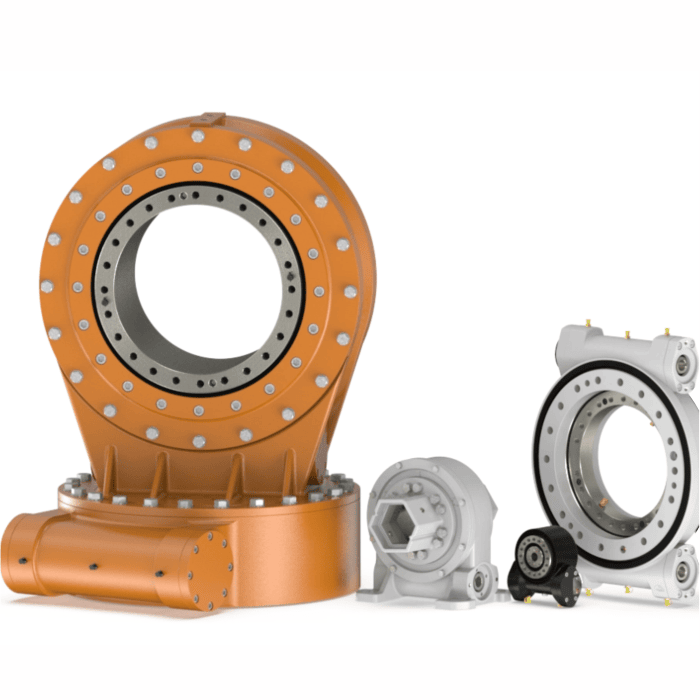

Slewing bearings and slew drives

Slewing bearings are rolling bearings with an inside diameter of more than 0.3 m. These bearings have the characteristic shape of the bearing rings, allowing them to be fixed directly to the machine by means of bolts.

Construction:

Slewing bearings consist of two or more rings between which the rolling elements are placed. Depending on the type of application, temperature and environmental conditions in which the bearing will operate, slewing rings are made of various types of steel. Slewing bearings are produced, for example, in 42CrMo4 steel.

Between the rings, special seals with different sections are installed to limit the ingress of dirt into the bearing. The bearing race is made of induction hardened steel on which the rolling elements in the form of balls or rollers move.

Due to the requirement of regular lubrication, the bearings are equipped with grease nipples placed in the rings.

Selection:

Slewing bearings are characterized by low rotation speed and are selected due to static loads. Attention is drawn to the axial force and the tilting moment which determine the operating point of the bearing.

The curves limiting the operating range - result from the maximum load capacity of the bearing and the load capacity of the bolted connection.

Reduced axial force - the sum of all axial and radial forces acting on the bearing increased by a safety factor (depending on the operating conditions of the application).

Reduced capsizing moment - sum of all mometas acting on the bearing increased by a safety factor.

Classification of large size bearings:

Classification by external structure:

bearings with external toothing

bearings with internal gearing

toothless bearings

Classification due to internal structure:

single row bearings

double row bearings

three-row bearings

Classification by type of rolling element:

ball bearings

roller bearings

Division according to the position of the rim on the bearing:

with a rim with internal toothing,

with external tooth rim,

Application in industries: wind farms, tower cranes, excavators, manipulators, positioners, rotating platforms, loaders, radars and antennas, bark beetles and forestry machines, aerial platforms, agitators and scrapers.

Slewing bearings consist of two or more rings between which the rolling elements are placed. Depending on the type of application, temperature and environmental conditions in which the bearing will operate, slewing rings are made of various types of steel. Slewing bearings are produced, for example, in 42CrMo4 steel.

Between the rings, special seals with different sections are installed to limit the ingress of dirt into the bearing. The bearing race is made of induction hardened steel on which the rolling elements in the form of balls or rollers move.

Due to the requirement of regular lubrication, the bearings are equipped with grease nipples placed in the rings.

Selection:

Slewing bearings are characterized by low rotation speed and are selected due to static loads. Attention is drawn to the axial force and the tilting moment which determine the operating point of the bearing.

The curves limiting the operating range - result from the maximum load capacity of the bearing and the load capacity of the bolted connection.

Reduced axial force - the sum of all axial and radial forces acting on the bearing increased by a safety factor (depending on the operating conditions of the application).

Reduced capsizing moment - sum of all mometas acting on the bearing increased by a safety factor.

Classification of large size bearings:

Classification by external structure:

bearings with external toothing

bearings with internal gearing

toothless bearings

Classification due to internal structure:

single row bearings

double row bearings

three-row bearings

Classification by type of rolling element:

ball bearings

roller bearings

Division according to the position of the rim on the bearing:

with a rim with internal toothing,

with external tooth rim,

Application in industries: wind farms, tower cranes, excavators, manipulators, positioners, rotating platforms, loaders, radars and antennas, bark beetles and forestry machines, aerial platforms, agitators and scrapers.