Are you sure you want to perform this action?

Opening hours

-

PLEWISKA

- Monday - Friday

- 7:30 - 16:30

- +48 61 60 00 100

- [email protected]

-

CONTACT 24/7

- Contact after office hours

- +48 61 60 00 102

-

KATOWICE

- Monday - Friday

- 7:00 a.m. - 4:00 p.m.

- +48 48 32 88 00 300

- [email protected]

-

OLSZTYN

- Monday - Friday

- 7:00 a.m. - 4:00 p.m.

- +48 89 89 89 350

- [email protected]

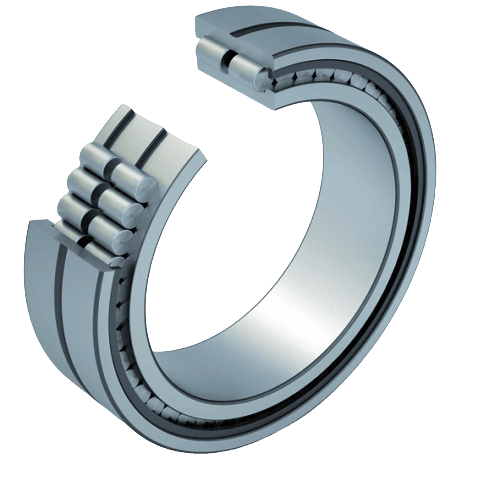

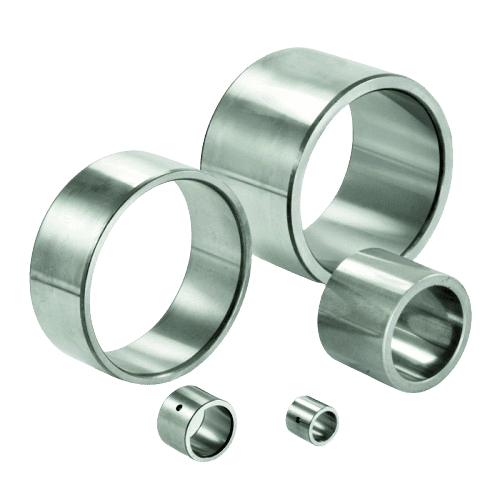

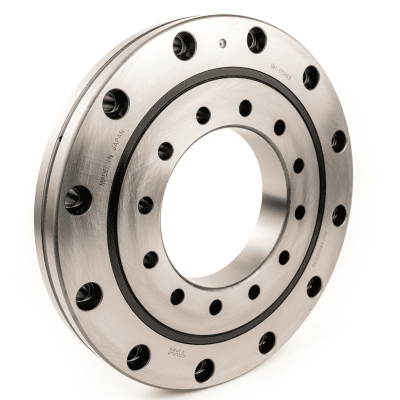

Cylindrical roller bearings

Cylindrical roller bearings are a type of rolling bearings that are detachable, which means that they can move slightly relative to the housing in which they are placed. Their design includes an outer ring, an inner ring, a raceway and rolling elements resembling a cylinder, which determines the name of this type of bearings. They are available in single, double, three and four row versions and as single and double row thrust bearings.

Exceptional durability

Cylindrical roller bearings, also called roller bearings, are considered to be one of the most durable ones available on the market. They are a popular choice in the assembly and production of machines with complex structures. Unlike other types of bearings, they have a separate ring, which facilitates the installation of subsequent components. Their impressive durability is up to 30 years, and their solid construction means that they do not require special maintenance.

Applications of Cylindrical Roller Bearings

Cylindrical roller bearings are used in various fields. They are used in the production of machines and lifting devices such as cranes, lifts and ramps. Basic models can also be found in the weaving and sewing industries, as well as in machine tools, manifolds and milling machines. It is worth emphasizing that they are also used in gears of crane structures, which proves their versatile use.

Types of Cylindrical Roller Bearings

Cylindrical roller bearings are available in various variants and types:

- fixed and unfixed,

- single and double-row,

- with or without basket,

- low friction

- high precision.

Design Advantages

A separate ring in the cylindrical roller bearing allows for convenient installation of subsequent parts and also enables complex work to be carried out. Additionally, the loose raceway allows the housing to move while the bearing is in operation. However, it is worth remembering that although they are extremely durable, it is recommended to lubricate or renew worn elements from time to time.

Summary

Cylindrical roller bearings are an irreplaceable solution, combining efficiency and reliability. Their versatile use makes them an indispensable element in many industries, and their durability guarantees reliability for a long time.