Ball screw mechanisms - design and application

/ 5 Reviews :

What is a ball screw mechanism?

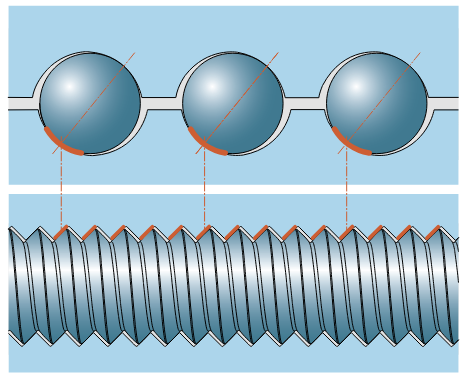

In answering this most basic question, it is worth noting, first of all, that ball screw mechanisms are machine elements that transform rotary motion into linear motion - and vice versa. Due to high precision, efficiency and reliability, they are widely used in many industries.

Types of ball screw mechanisms.

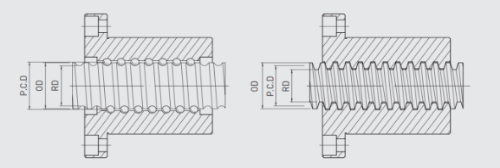

There are two main types of ball screw mechanisms:

- Ball screw mechanisms: They use balls as rolling elements ensuring high precision, efficiency and low friction.

- Planetary mechanisms: Used in heavy-duty applications, instead of balls, rollers with a thread similar to metric are used.

Fig. 1. Comparison of ball and planetary threads (EWELLIX graphics).

Ball screw mechanisms can be divided into 3 main groups depending on the method of making the screw:

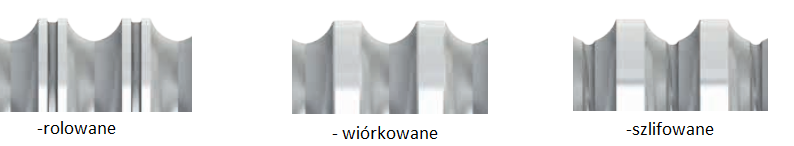

- Rolled: made in the cold rolling process, characterized by a flash on the outer diameter, the most popular type with the best availability without the requirement to pair the nut with the screw in the option without or with radial-axial clearance removal, accuracy classes T5-T10.

- Punched: made with a special tool intended for the punching process, screws paired with nuts, accuracy classes T5-T7.

- Grinded: the most accurate drives, characterized by a groove at the bottom of the thread (removal of ground material), intended for the most precise applications, nuts always paired with screws and with eliminated radial-axial play, accuracy class T0 -T5.

Fig. 2. Ball screw types (HIWIN graphics).

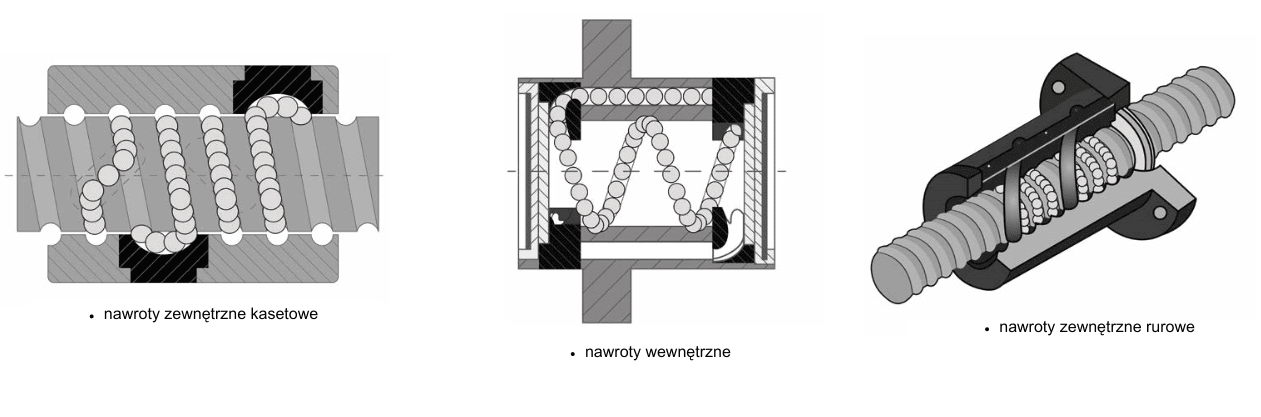

Nuts of ball screw mechanisms can be divided according to the type of turns (internal and external) and external shape (single, double, with a collar, cylindrical, with metric external thread, with adjustable tension)< /p>

The design and principle of operation of the ball screw mechanism.

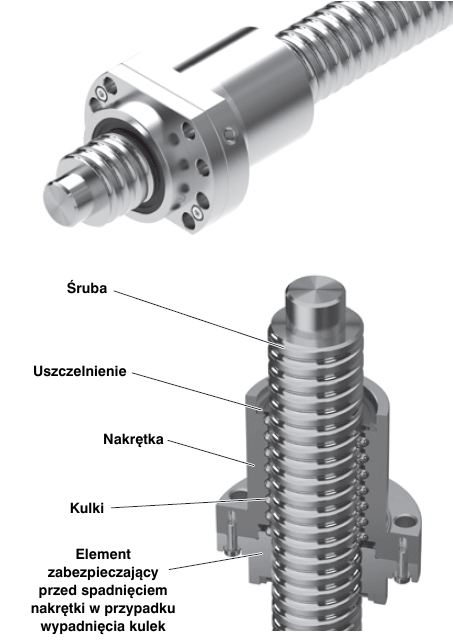

Fig. 3. Example of a nut structure with external tubular turns (graphics from the THK catalogue).

The basic elements of the ball screw mechanism are:

- Screw: shaft with ball thread.

- Nut body: element with internal ball thread.

- Rolling elements: Precisely made and selected balls that minimize friction and ensure smooth operation in the application.

- Reversals: ensure correct circulation of rolling elements (balls) in an endless loop.

- Seals: prevent dirt from entering the nut. They are available in plastic, bronze and with brushes.

Fig. 4. The most popular types of relapses (NTN-SNR graphics).

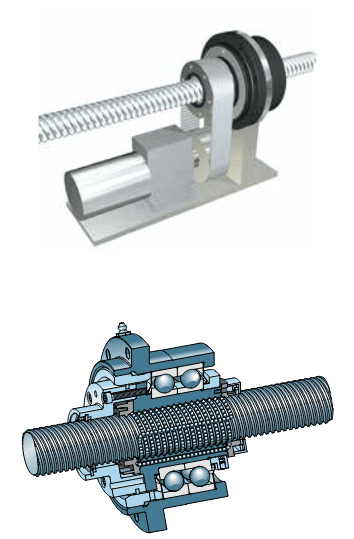

The rotation of the screw causes the nut to move along its axis. Ball screw sets are available with many possible pitches (linear displacement of the nut per one revolution of the screw), from 1 [mm] to even 100 [mm] and an equally large range of screw diameters. Sets with a nut are also available to achieve linear movement in the screw axis.

Fig.5. The concept of the mounted driven nut and its structure (Ewellix graphics).

Nuts are available with special protection against uncontrolled falling of the nut in the event of ball destruction.

Fig. 6. Protection of the nut against falling in the event of a failure (Bosch Rexroth graphics).

Applications of ball screw mechanisms

Roll screw mechanisms are widely used in various industries and machines, they can be found in applications such as:

- Machine tools: Milling machines, lathes, drilling machinesand other CNC machines use ball screw mechanisms for precise positioning of tools and workpieces.

- Robots: Robotic arms are based on ball screw mechanisms to obtain smooth and precise movements, the so-called ball spline, connection of a ball screw with a rolling sleeve transmitting torque (this allows for a multitude of movement characteristics).

- 3D printers: Ball screw mechanisms ensure precise movement of the print head in the X, Y and Z axes.

- Medical devices: Operating tables, MRI machines and other medical devices use ball screw mechanisms to ensure smooth and stable movement.

- Packaging machines: Ball screw mechanisms are used in the transport and positioning of products in packaging processes.

- Electric actuators: used as an alternative to hydraulic and pneumatic actuators, the ball screw mechanism is responsible for the linear movement of the piston.

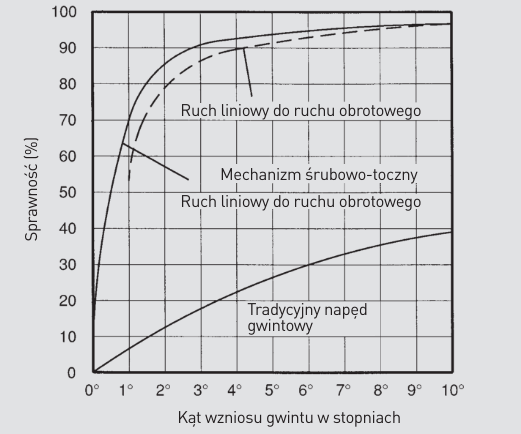

Efficiency of ball screw sets

The efficiency of the ball screw mechanism is much higher compared to traditional trapezoidal screws, efficiency reaches up to 90%. This is due to the use of rolling elements, which significantly reduce the friction coefficient. All components are hardened, which significantly extends the service life.

Fig. 7. Comparison of ball and trapezoidal threads (HIWIN graphics).

Fig. 8. Chart of the efficiency of screw drives depending on the type and angle of the ball screw thread (HIWIN graphics).

The thread pitch angle results directly from the pitch and diameter of a given set, the larger the angle, the greater the pitch.

Where to buy ball screw mechanisms?

Are you looking for high-quality ball screw mechanisms? The Albeco store offers a wide selection of mechanisms from renowned manufacturers such as EWELLIX, HIWIN, THK and REXROTH. The store's offer includes ball screw mechanisms with various technical parameters, adapted to various applications. Additionally, Albeco provides professional advice in selecting the appropriate mechanism and offers fast delivery and competitive prices.

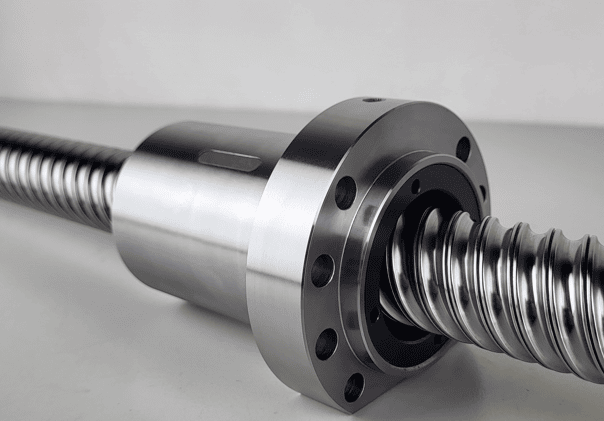

In addition, we very often deliver special sets with nuts of unusual shapes and with eliminated radial and axial play. This is particularly useful in the event of failure of very old ball screw sets with unusual dimensions. often these sets are no longer produced and changing the control or modifying the mounting in the application is impossible.

Depending on the level of complexity, we can prepare special sets at ALBECO's headquarters even within 1 business day. this is due to our extensive technological and engineering resources.

Photo. 9. An example of a special set made by ALBECO.

At Albeco, we regenerate ball screw sets. The scope of our activities includes diagnosis, valuation and regeneration after the customer accepts the costs. Additionally, at the customer's request, we create technical documentation and quote a factory price for a new ball screw assembly. Depending on the level of complexity and current processing capacitywe are able to perform regeneration even within one business day.

We encourage you to familiarize yourself with the offer of the Albeco store and take advantage of professional advice on the selection of ball screw mechanisms.

If you have questions about ball screw mechanisms, please contact our specialists:

Michał Dłutkowski

Technical Specialist - Linear Technology

Technical Specialist - Linear Motion

|

[email protected] |

|

tel: +48 61 60 00 160 |

Jakub Kulig

Technical Specialist - Linear Technology

Technical Specialist - Linear Motion

|

[email protected] |

|

tel: +48 61 60 00 162 |

Leszek Wolny

Head of the Technical Department

Technical Manager

|

[email protected] |

|

tel: +48 61 60 00 194 |

Read more