Erredi clamping elements

/ 5 Reviews :

ERRE.DI clamping elements are characterized by:

- high holding force with minimal dimensions,

- very easy installation,

- backlash-free blocking of the thread during processing,

- no movement relative to the workpiece and therefore no wear of the locking elements,

- meeting safety requirements (e.g. in vertical axes),

- keeping the system in place in the event of a power failure,

- excellent price-performance ratio.

The aluminum elements of the clamps are hard anodized, and the steel elements are nickel-plated. This provides the clamping elements with corrosion resistance. The pressure forces of the clamping elements act on the rail evenly. High system efficiency and fast clamping make these mechanisms particularly suitable for use in linear motors and machine tools, as well as in a variety of transfer systems. The wide range of products offered is able to meet the various needs of customers.

Hand clamp for FRCMAN LT guides and FRCCMAN shafts is a simple and reliable manual clamp. Turning the lever causes the lock jaws to simultaneously clamp on the profile rail/shaft, and the self-adjusting jaws ensure symmetrical distribution of forces on the linear guide.

Click on the link to see catalog cards: PL and ENG

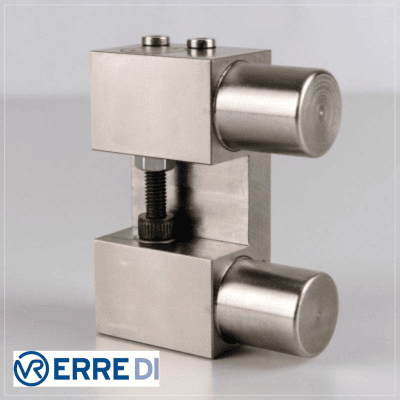

FRC pneumatic clamp. The clamping is done via a wedge gear. Made of structural steel ensuring high axial and radial stiffness.

Click on the link to see catalog cards: PL and ENG

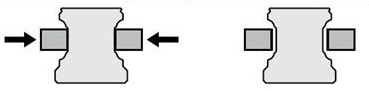

How do pneumatic clamps work?

The surfaces of the locking jaws are pressed against the guide using a double wedge mechanism. The release and unlocking takes place instantly thanks to a system of pre-tensioned springs.

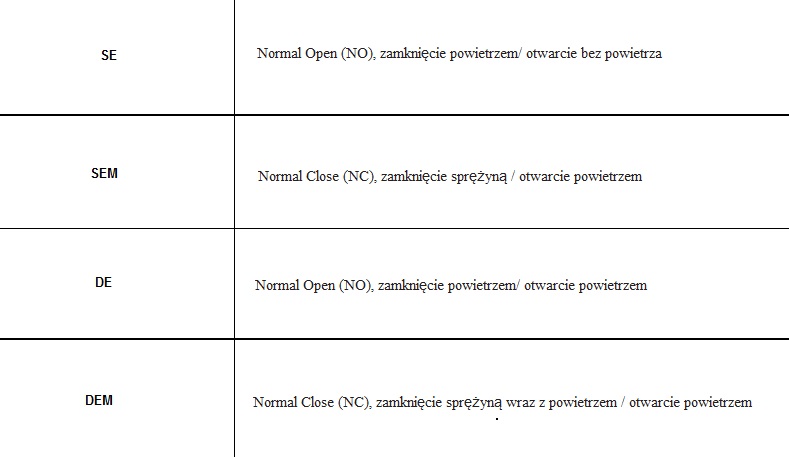

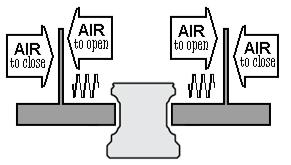

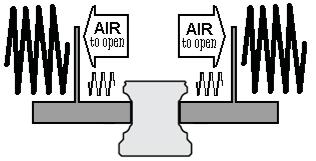

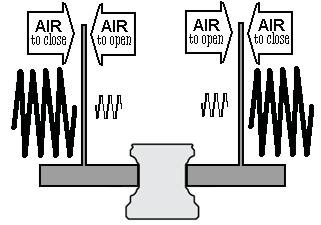

Four types of pneumatic clamps:

- SE: Normal Open (NO), closing with air/opening without air.

The lock is tightened by air supply. Opening occurs when the air is cut off.

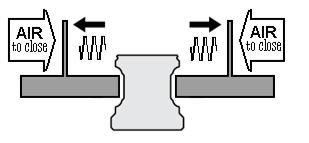

- DE: Normal Open (NO), air close/air open

The principle of operation is the same as in point A, except that the clamp opens with air. The air vent was replaced by a second air line (a 5/2 diverter valve was used).

- SEM: Normal Close (NC), spring closing / air opening.

Clamping is done using a spring, opening is done using air.

- DEM: Normal Close (NC), spring closing with air / opening with air.

The spring pressure has been increased by supplying 5/2 air through the distribution valve. In this case, the clamping force increases 2.5 times.

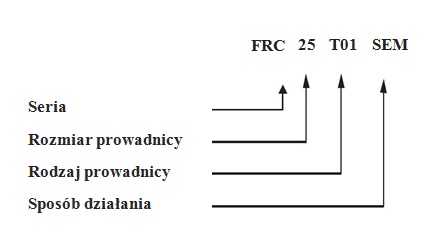

Clamp designation:

Symbols of individual series:

- FRC

- FRCDP

- FRCBS

- FRCMAN LT

The size of the guide corresponds to the size of the guide on which the clamp is mounted. This is also the lock size.

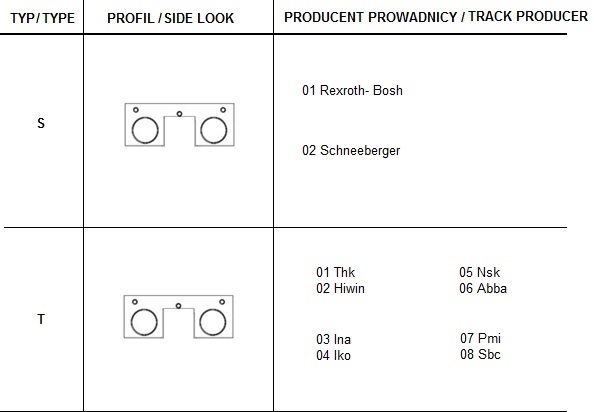

Guide type is a parameter referring to the model of the linear guide on which the clamp is mounted (corresponds to the profile of the locking elements in the clamp location).

Table with the designation of the track type table.

Designation of the operating method of pneumatic clamps:

Type of work table: