Ensure effective sealing with SKF Speedi Sleeves

/ 5 Reviews :

Regenerative bushings are a solution to problems with worn shafts, without the need for disassembly or size change. The new generation of SKF SPEEDI-SLEEVE offers even better performance of the sealing system.

ENSURE EFFECTIVE SEALING.

To ensure an effective seal, radial shaft seal rings must engage a smooth, round surface on the shaft. When this surface becomes worn, the seal will no longer be able to perform its functions of retaining lubricant and protecting against contamination. When a particle of dirt gets under the sealing lip and rubs the shaft, it usually scratches the mating surface, causing a leak.

Simply replacing the seal is not enough, and repairing the shaft usually requires dismantling the machine so that the shaft can be ground or metalized. The use of SKF SPEEDI-SLEEVE regeneration sleeves does not require this procedure, it is easier, more efficient and more economical.

FAST AND EASY SOLUTION.

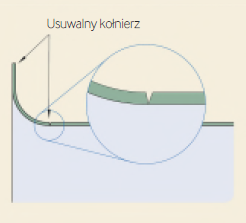

The SKF SPEEDI-SLEEVE bushing replaces machining, provides an appropriate surface and is easy to install. The removable collar does not affect the interaction with other elements and does not impede the supply of lubricant (photo 1).

photo 1. Removable collar on the SKF SPEEDI-SLEEVE sleeve

The use of SKF SPEEDI-SLEEVE when installing new equipment allows for savings and extending the durability of the surface cooperating with the seal.

NEW GENERATION

SKF SPEEDI-SLEEVE bushings made of high-quality stainless steel offer an optimal contact surface, reduce wear of the bushings and sealing lips. Grease pockets minimize the risk of seal dry operation, increasing the durability of the sealing system and its stability, and allow for greater planning of the operation and maintenance of the entire system. Using a sleeve together with a sealing ring increases durability.

SKF SPEEDI-SLEEVE bushings have been subjected to abrasion resistance and durability tests. Tests have confirmed a reduction in surface wear and wear fluctuations thanks to the new generation of bushings (500-hour abrasion test and 2000-hour durability test).

WIDE RANGE OF APPLICATION

SKF SPEEDI-SLEEVE bushings are a solution known and used in:

• industrial gears

• electrical devices (engine shafts),

• in construction and agricultural machines,

• in industrial pumps - increase efficiency, reduce costs thanks to the optimal contact surface with the seal without the need to process shafts,

• in mining - in mineral processing, cement production, crushers, conveyors, engines, reducers, fans, gears and pumps, increase productivity and profitability, reducing maintenance and repair costs, as well as meeting environmental standards and regulations because they minimize risk leakage of lubricant into the environment (photo 2).

photo 2. SKF SEEDI-SLEEVE

Benefits of using sleeves:

• quick and easy service solution = effective product life cycles,

• improved sealing system ensures increased mean time between failures (MTBF),

• life cycle cost control thanks to simplified operating procedures

• greater protection of the system (bearings and gears),

• increased equipment productivity and reliability (field repairability, better sealing performance and lower repair costs).

WIDE CHOICE OF VARIANTS AND SIZES

SKF SPEEDI-SLEEVE sleeves are available in diameters from 12 to 203.2 mm. For larger diameters (211 to 1143 mm), recovery sleeves with a different design are available. SKF SPEEDI-SLEEVE sleeves are available in the SKF SPEEDI-SLEEVE Gold version, for more abrasive environments and whenSeals made of reinforced PTFE are used.

Photo: SKF SPEEDI-SLEEVE bushings are available for shaft diameters from 12 mm to 203.2 mm.

SKF SPEEDI-SLEEVE can be used in shaft seals up to 203.2 mm in diameter, offering an economical and quick solution for improving seal performance. Increase your safety and reliability with the revolutionary SKF SPEEDI-SLEEVE bushings! By combining sleeves with SKF rings, you can be sure that your shaft seal will be more durable and even.

This makes maintenance planning more stable and the service life more predictable. Take advantage of this great opportunity to increase the reliability of your sealing system!

Read more