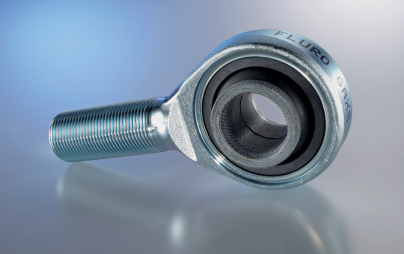

Rod ends and spherical bearings

/ 5 Reviews :

COUPLING TOWING AND SPORT BEARINGS.

Rod ends and spherical bearings are ready-to-install machine components used for bearing arrangements where there is a need to compensate for movement between the shaft and housing or when the bearing performs simultaneously pivoting and rotating movements.

Spherical bearings consist of two rings. The spherical outer surface of the inner ring is convex, while the outer ring has a concave inner surface.

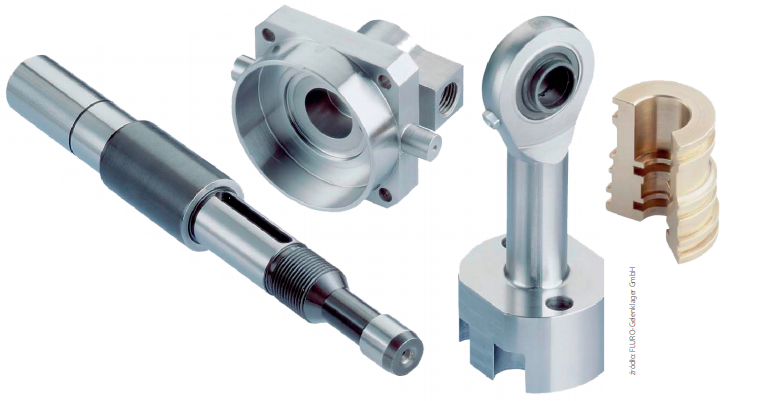

Rod ends additionally consist of a threaded spindle mounting element. They are ready for installation and can be quickly and easily attached to the machine structure. The market offers technical solutions based on the use of various cooperating pairs of frictional materials (steel with steel, steel with bronze, steel with PTFE) and various construction versions resulting from the requirements for assembly & mdash; with right or left internal or external thread.

While the market of rolling bearings is largely dominated by the offer of the world's largest concerns, plain bearings have become the domain of medium-sized manufacturers. They base their market success mainly on high specialization, advanced technology and flexibility in relation to market demand. An example is the German company & nbsp; FLURO Gelenklager GmbH, specializing in the production of spherical bearings and rod ends.

The origins of the company date back to the 1970s, when Martin and Ernst & nbsp; H & ouml; hn founded the company Martin H & ouml; hn GmbH (Ltd.) , where the production of precision subassemblies was started using turning and grinding machines. w for machines. & nbsp; In 1976 the company FLURO Gelenklager & nbsp; GmbH was founded, which took over the production of plain bearings and rod ends started a few years earlier.

High-quality products quickly gained customers, and the company signed numerous foreign contracts. The previously offered plain bearings requiring relubrication have been largely replaced by maintenance-free bearings. The company focuses on the production of spherical bearings and rod ends to this day.

FLEXIBILITY AND SPECIALIZATION

Rod ends and spherical bearings are used in & nbsp; all industrial sectors : & nbsp; paper, tobacco, in food processing and in the production of packaging.

Significant customers are also the construction sector, the automotive industry, the railway industry, the aviation industry and the wood processing industry. A special recipient of articulated bearings and rod ends is heavy industry, where a number of requirements are combined: extreme temperatures, high loads, vibrations and pollution. Products used in industry must undergo thorough control at every stage of production. The introduction of a new version or product is preceded by detailed material and construction tests with the use of modern measuring equipment and the construction of prototypes.

One of the most important tests is material and construction testing with the use of modern equipment. It includes hardness measurement and static tensile and compression tests of the material at room temperature and elevated to 1200 & deg; C . Additionally & ndash; with the help of measuring machines & ndash; precise scans of dimensions, geometry and roughness are made. & nbsp;

Particular emphasis is placed on the durability test in the case of bearings designed to operate in extreme temperatures, with high vibrations and with heavy and difficult to eliminate contamination.

& quot; Fluroglide spherical bearings are completely maintenance-free, maximum static and dynamic load capacity, low slip effect and increased service life. & quot;

& nbsp;

A long phase of material and construction research carried out by FLURO allowed for the development of the FLUROGLIDE series. These products use a special material with high abrasion resistance that allows you to work in temperatures from -50 ° C to 720 ° C . Products of the & nbsp; FLUROGLIDE & nbsp; series are resistant to various contaminants such as: oil, s & oacute; l, dust, soot and sand, and when working with vibrations above 50 Hz, they show no signs of wear.

AESTHETIC SPORT BEARINGS.

The external appearance of machinery and vehicle components is usually irrelevant. Particular recipients in this respect are manufacturers and users of sports vehicles: quad, racing and tuned cars.

Series of products for motorsports & nbsp; FLURO MOTORSPORT & nbsp; is used wherever durability, resistance to pollution and high temperatures, maintenance-free, and additionally, attractive, sporty appearance. Typical automotive applications are the suspension system, stabilizers and the steering system. Rod ends and spherical bearings of FLURO MOTORSPORT are maintenance-free and feature a reduced bearing play.

The bushing, both in the articulated bearings and in the rod ends, is made of stainless steel 1.4571 combined with a PTFE layer. The steel used is a grade with the addition of stabilizing titanium. It is used to reduce the risk of intercrystalline corrosion during annealing at the temperature of 425-815 ° C. By creating carbides, titanium also prevents the formation of chromium carbide.

This prevents intercrystalline corrosion and provides improved mechanical properties, especially at temperatures above 600 ° C. The inner ring is made of 100Cr6 steel and is hardened and coated with a layer of hard chrome. & Nbsp; The bearing housing made of nickel-plated and polished 42CrMo4 steel provides an attractive, sporty look, especially important in the case of visible elements.

The surface finish also provides high protection against corrosion and minimizes the build-up of dirt and facilitates cleaning.

An example of an application of the MOTORSPORT product series are ball joints used in cars prepared by teams from Wrocław and Poznań University of Technology.

Teams have been participating in the Formula Student program for many years & mdash; international competitions organized by the Institution Of Mechanical Engineers for student teams from all over the world, who independently design and build a racing car. Teams of young designers have used FLURO joints in the wishbones, the link between the wishbone and the steering knuckle, steering rods, and the pull-rod damping system rods, where they are loaded by dynamically varying forces acting on the suspension system. The design of the suspension components is designed to minimize the bending moments that act on the threaded pin to reduce the risk of overstressing at this point.

Throughout the period of use, all the elements used have proved to be reliable and are used by teams each time during subsequent editions of the competition.

The market offer of rolling bearings, the number of design and material solutions, as well as lubrication solutions is so large that plain bearings, including spherical bearings and rod ends, are often wrongly overlooked in studies and publications on bearing issues. However, these products constitute a very important part of the market, they cover a wide range of applications, being irreplaceable for many applications.

Specialized manufacturers provide a wide range of products, adapting them to a given application and unique requirements in terms of dimensions, parameters, design and aesthetics.