Schaeffler Optime - Supervision of the machine park

/ 5 Reviews :

OPTIME. Plug, Play. Predict. Enter a new era of machine monitoring.

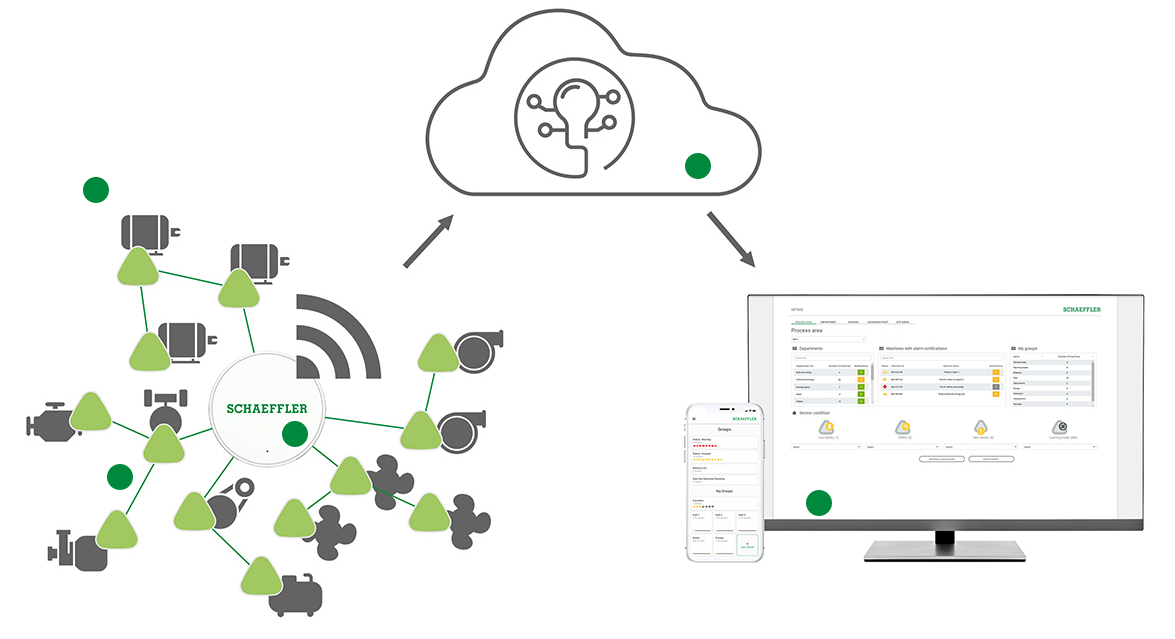

How does OPTIME work?

1. Plug in.

- Simple and quick installation in a tapped hole or glued washer with a tapped hole.

- Automatic networking.

- Mesh network - one of the most effective and reliable IoT networks in industry.

- The system can be extended with additional measuring points at any time.

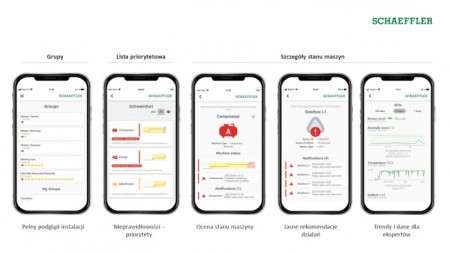

2. Play.

- Intuitive operation for novice users and experts.

- Visualization of trends and severity of possible defects.

- User defined grouping of monitored devices.

- Warnings and alerts - in-app notifications.

- Digital services for professional diagnostics, available 24/7 via the app.

3. Predict.

- Continuous, automated analysis based on expert algorithms and machine learning.

- Detects anomalies several weeks in advance and indicates their causes.

- Allows you to take action in advance and plan your spare parts purchases.

4. Order the Schaeffler OPTIME system and take advantage of the Albeco FREE diagnostic support.

- Consulting and technical support. Selection of the optimal machine and device diagnostics system based on OPTIME for the client.

- Support in system installation and diagnostic devices assembly.

- Indication of the best measurement locations or the location of the gates.

- Installation of the OPTIME software on mobile devices with user registration.

- We provide training for employees operating the application - system administrator, and optionally full diagnostic training for a larger group of employees.

5. Additional services.

- We offer the possibility of preparing additional monthly or weekly reports summarizing the work of monitored devices.

- We offer additional support in machine health monitoring and devices. In the event of a condition indicating a potential failure, we additionally contact the system administrators.

- We carry out periodic visits to check the state of devices and system operation.

- Ongoing service of the installed monitoring devices and, under the contract, replacement of devices with new ones.

How does the system and its components work?

- Quickly install battery powered sensor on machines.

- Wireless sensors record vibration and temperature for automatic machine diagnostics.

- The gateway receives data from the sensor and forwards it to the cloud.

- Digital services analyze data and report the results for professional evaluation in a convenient way via a smartphone app or PC app.

If the sensor is damaged or is overloaded, the network will correct the connections itself. An unconnected sensor will find a new path to the gate. Structural barriers are not an obstacle.

Benefits of using OPTIME.

- Hassle-free monitoring at the lowest cost.

- Monitoring of hundreds of rotor machines for only a few zlotys a day per point.

- Quick Install.

- Installing the sensor and activating it via the app takes a few minutes - no special knowledge required.

- Using expert knowledge

- Digital services deliver professional diagnosis based on expert algorithms and machine learning, available 24/7 via the app - the right decision is always made.

- For beginners, user and expert.

Intuitive operation provides comprehensive information for decision making by different users with different needs. - Pre- and post-sales consultancy Diagnostics expert at Albeco.

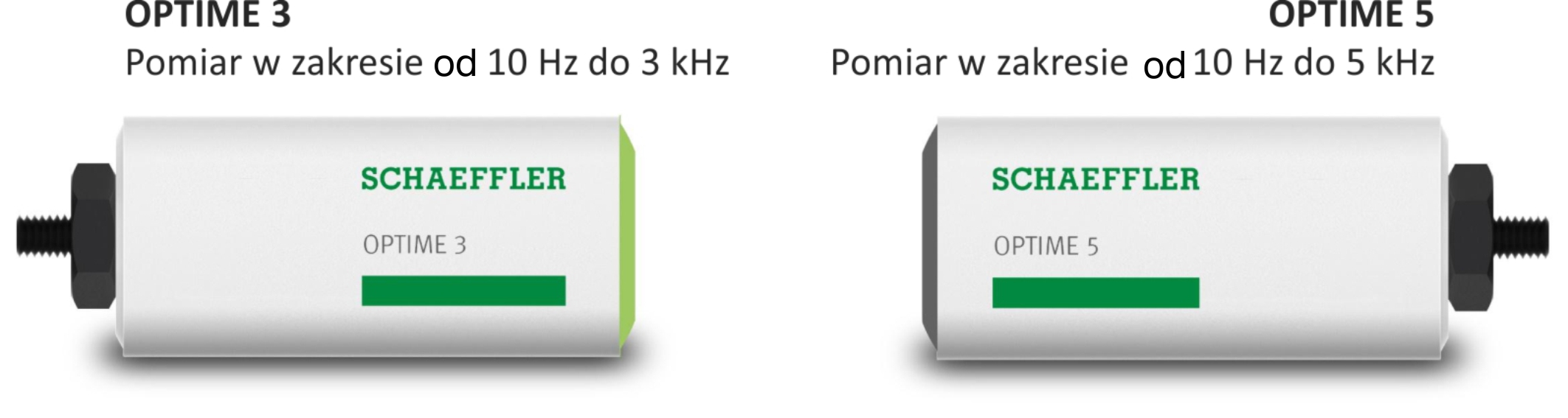

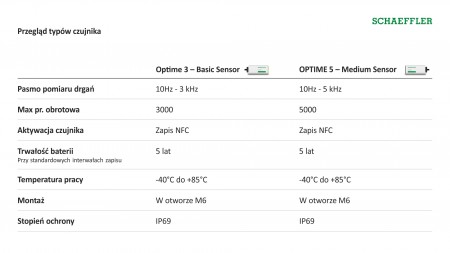

Which sensors to choose?

A digital cloud service. Industry 4.0 - use the solutions of the future that are at your fingertips.

One application for all user groups

OPTIME Digital Service.

It is a cloud-based solution that can be used via mobile and web applications for desktop browsers, e.g. in control rooms or at the workplace. At the same time, a dedicated customer area will be created as part of the Schaeffler cloud service. The client manages the OPTIME installation using the mobile application or the OPTIME application on the computer's desktop. A digital service consists of a mandatory service and additional optional services. Compulsory service elements. Monthly subscription to a digital cloud service. The subscription to the service consists of access to your own customer area in the Schaeffler cloud. & Nbsp; Allows user access and management of the customer area. The subscription allows you to run and activate sensors and gates via a mobile application, and allocate equipment, create monitored machine positions and assign them to appropriate groups.

- Access to mobile and web applications for desktop browsers.

- Gateway SIM card data costs are included in the monthly charge.

- Monthly subscription to digital service analytics (cloud data).

- The system automatically analyzes the state which is based on vibration.

- Monitored machines are evaluated by the system using automatic, algorithm-based diagnostics.

- The OPTIME application displays alarms and failure causes.

- You only pay for active sensors.

- The sensor is active as soon as Schaeffler Cloud receives measurement data from the sensor.